- Niob, like most refractory metals, also has a high melting temperature and is therefore also heat resistant.

- As a result of the formation of a passive layer (protective layer), niobium in the air is very resistant. Most acids therefore do not attack it at room temperature. Only hydrofluoric acid, especially in the mixture with nitric acid, as well as hot concentrated sulphuric acid corrode metallic niobium quickly.

- In hot alkalis, niobium is also volatile as it dissolves the passive layer.

- Niobium is very ductile and therefore very easy to forming

- Niobium is superconducting below -267°C

- Nb has low neutron capture cross-section

Characteristics of Niobium

| Symbol | Nb |

| Melting point | 2.468 °C |

| Density | 8,57 g/cm³ (25°C) |

| Modulus of elasticity (E-module) | 104 GPa |

| Poisson Number | 0,34 |

Use of Niobium

- Niobium and its alloys are used in chemical process engineering as a construction material.

- In electronics as a component of superconductors or capacitors

- In nuclear technology for reactor components.

- Niobium is used in the jewelry industry or as a coin metal.

- Nb is used as an alloy surcharge for Super Alloys

- Nb is used as an alloy surcharge in steel production

Important Niobium Alloys

| Nb 99,8% | R04200 | type 1 – Reactor quality, Ta <0,1 %) |

| Nb 99,6% | R04210 | type 2 – Standard quality, Ta <0,3 %) |

| NbZr1 | R04251 | type 3 – Reactor quality) |

| NbZr1 | R04261 | type 4 – Standard Quality) |

| NbHf10Ti1 | R04295 | |

| Nb7.5Ta | Niobium 7.5% Tantalum | |

| Nb47Ti 53 | Niobium 47% Titanium | |

| Nb50Ti 50 | Niobium 50% Titanium | |

| Nb55Ti 45 | Niobium 55% Titanium |

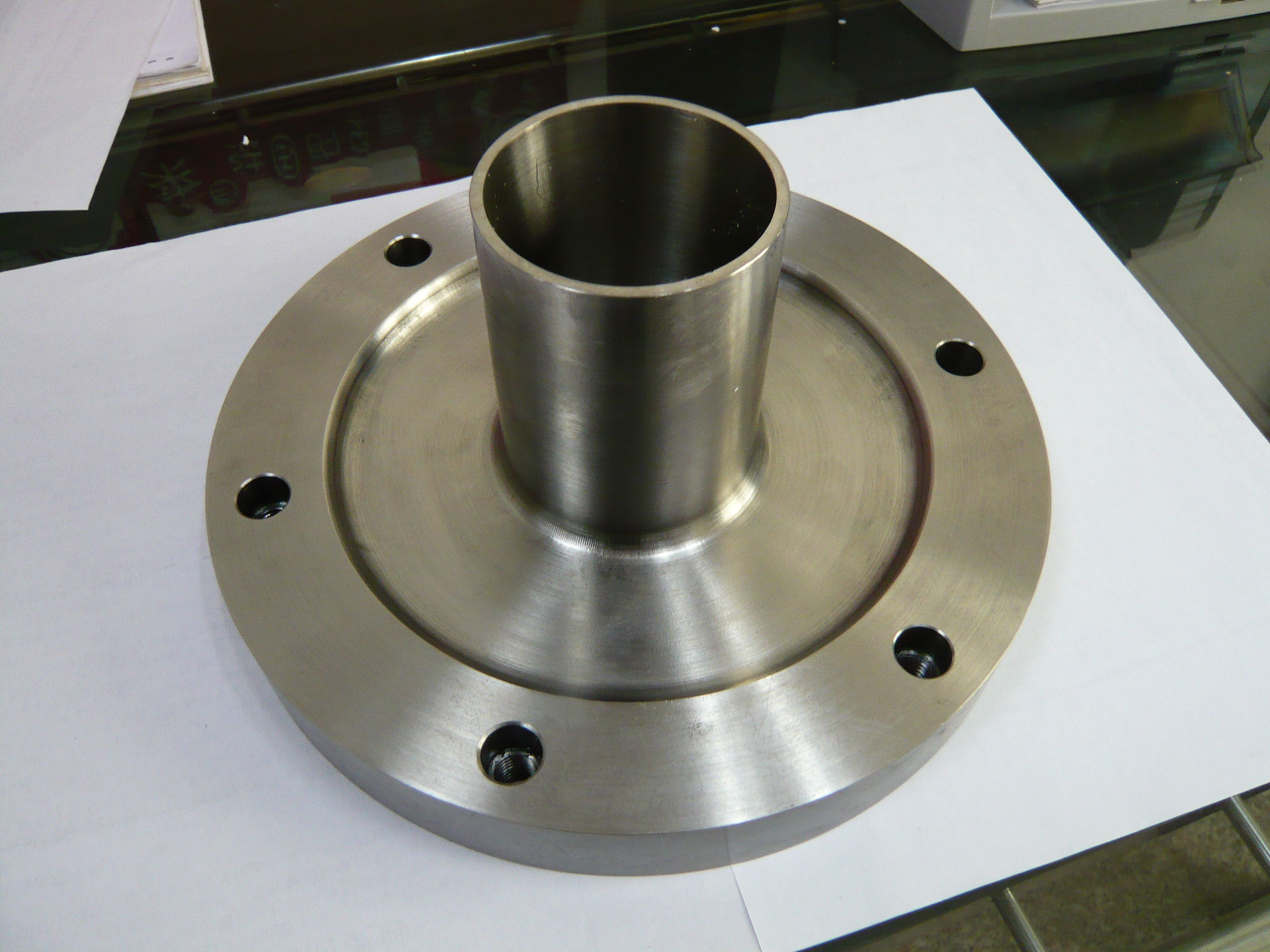

Niobium Products

| PRODUCT | SIZE RANGE | STANDARD |

|---|---|---|

| Nb Bars | Dia 3,0-110 mm | ASTM B392 |

| Nb Wire | Dia 0,5-5 mm | ASTM B392 |

| Nb Sheet + Foil | 0,03 mm-0,20 mm | ASTM B393 |

| Nb Tubes seamless + welded | AD2-105 mm x WT0,3-6,0 mm | ASTM B394 |

| Nb Ingots + Gussblöcke | ASTM B391 | |

| Nb Fasteners | ASTM B392 |