Zirconium and Zirconium Alloy In 1789 has been discovered by the chemist Martin Heinrich Klaproth.

Zirconium is mainly obtained from zirconium sands (ZrSiO4) and Baddelites (ZrO2), which are most common in Australia.

Zirconium and zirconium alloys are among the reactive metals.

Zirconium is very corrosion resistant. Zirconium has a passivating oxide layer (ZrO2), which renews itself again and again when in contact with water-containing media.

Among other things, zirconium Zr702 offers resistance to almost all organic acids, mineral acids and alkaline solutions.

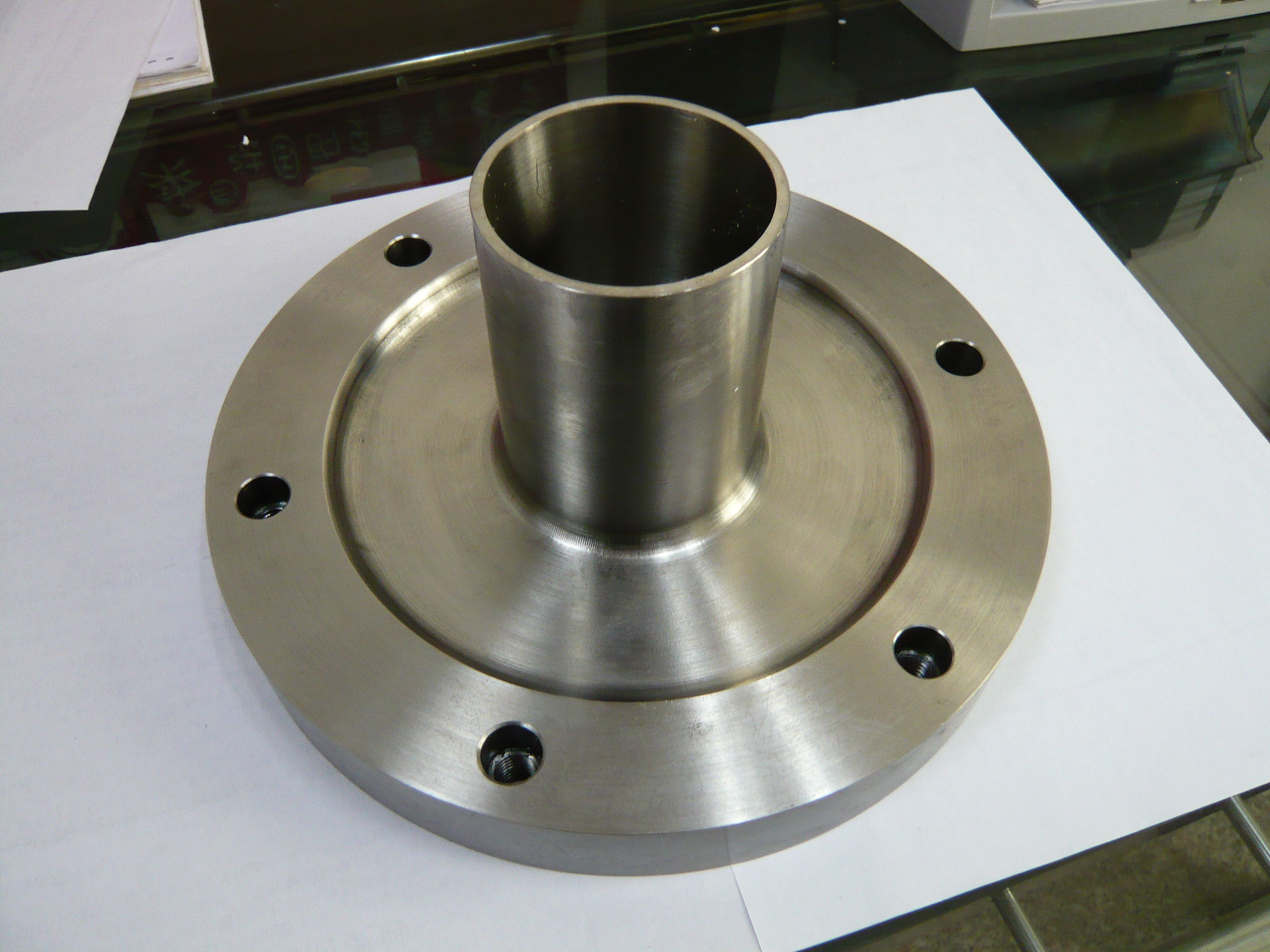

It is used in the construction of chemical plants, for example for valves, pumps or agitators. In electronics, it is used for the production of vacuum tubes for X-ray technology.

Zirconium semi-finished products and zirconium alloys

Today, semi-finished products made of zirconium are mainly used in the nuclear and chemical industries, with the materials used mainly differing by the remaining hafnium content.