- Molybdenum has a very high melting temperature and is used in the lighting industry.

- Mo is predominantly produced powder metallurgically.

- The main application of molybdenum is the steel industry as an additive, and especially in the production of stainless steel.

- In rocket production, Mo is used for the production of the nozzle elements, and other high-temperature-loaded construction elements, thermal shields, etc.

- In electronics, Mo is used in the production of X-ray tubes, as catodes and as a sealing element between glass and metal. In high-temperature furnaces,

- Mo is used as heating coils.

- Mo is also used as fastener screws and nuts in high-temperature applications.

Characteristics of Molybdenum

| Symbol | Mo |

| Melting point | 2625 °C |

| Density | 10,3 g/cm³ (25°C) |

| Melting temperature | 1668 °C |

| Modulus of elasticity (E-module | 310 GPa |

| Poisson Number | 0,30 |

Available Mo products

Pure Molybdenum 99,95%

| PRODUCT | SIZE RANGE | STANDARD |

|---|---|---|

| Mo Bars | Dia1,0-50mm | ASTM B386

ASTM B387 |

| Mo Wire | Dia 0,025-3,5mm | ASTM B386

ASTM B387 |

| Mo Foil | 0,025mm-0,10mm | ASTM B386

ASTM B387 |

| Mo Sheets | 0,15mm-15mm | ASTM B386

ASTM B387 |

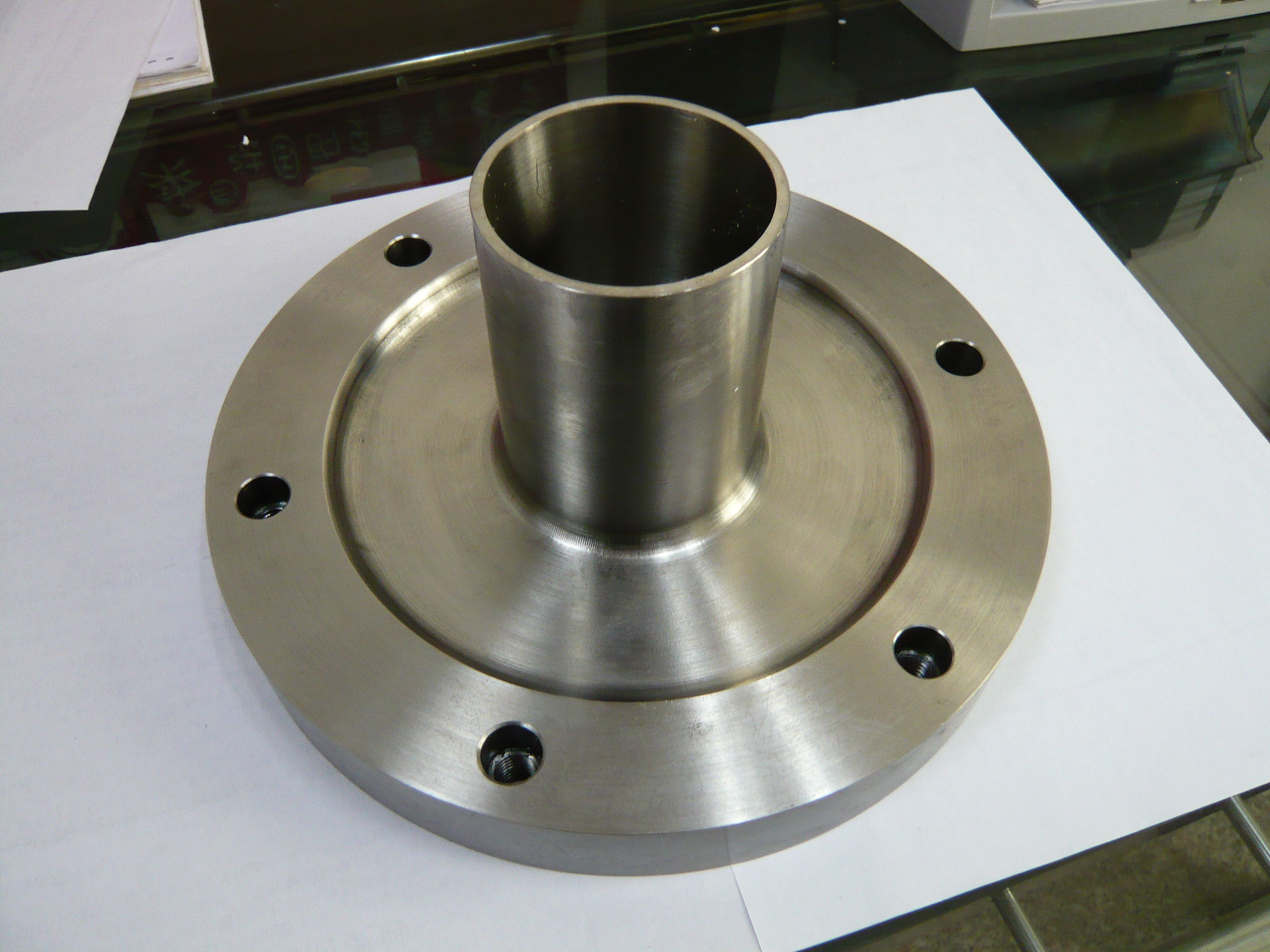

| Mo Fasteners | M1-M20 | ASTM B386

ASTM B387 |

| Mo Machined parts |

TZM Molybdenum 99,95%

- TZM is a molybdenum alloy of 0.5%Ti+0.08% Zr+0.02%C

- TZM is produced powder metallurgically or as a melt

- TZM has better strength and stretch and toughness than pure Mo.

Comparison Mechanical u Properties Mo and TZM:

| MATERIAL | PURE MOLYBDENUM 99,95% | TZM |

|---|---|---|

| Desity in g/cm³ | 10,30 | 10,22 |

| Tensile strength Mpa | 1035 | 760 |

| Elongation % | – | 15 |

| Modulus of Elasticity | 310 | 320 |

TZM is also produced according to the AMS 7817 standard.